I love the internet. Before it came along (yes, I run with the dinosaurs), I relied on magazine subscriptions like Dirt Bike, Hot Rod, and of course the legendary Crutchfield catalog for research. That’s where I’d find all kinds of low-dollar solutions to problems on my various mechanical monsters. Those resources still exist, but the internet is overflowing with ideas and solutions I never would have thought of on my own.

That brings me to this article. I picked up this idea from someone on another UTV forum, and it addresses what I consider a design flaw on the Polaris RZR Pro R. Sure, more expensive aftermarket solutions are out there, but why spend that kind of money when you can fix the problem for about $14? For me, it was a no-brainer.

If you’re a Pro R owner who does your own maintenance, this idea is extremely handy. When changing the oil on the Pro R, you have to remove the entire rear bed just to access the oil filler. It’s only four bolts, but if you’re running a cargo box or have other gear back there, it turns into a lot more work than it should be.

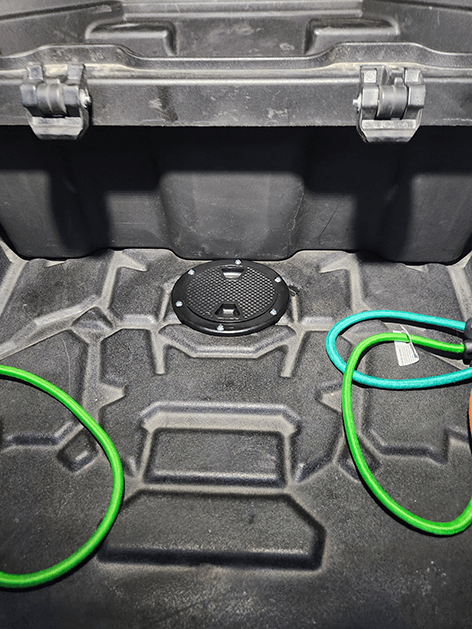

This solution works really well with using a boat inspection hatch deck plate. By cutting a hole in the bed directly above the oil filler and installing the hatch, you can access the filler cap simply by opening the hatch. No more screwing around detaching things that can only be detached so many times before something gets broke.

I took photos throughout the process to show how easily this can be done with basic tools most people already have in their garage. The only tool you might not have is a handheld jigsaw, but even that isn’t a deal breaker. The cut can be made just as easily with a box cutter by heating the blade.

Bottom line, the final result turned out better than I expected, and I had it done in a couple of hours. That’s slow by most standards, but I tend to be meticulous. As a bonus, the hatch also clears the outer edge of the cargo box perfectly. Sure I could have bought an aftermarket filler tube, but why? There’s something satisfying about building a clean, functional solution yourself.

I love seeing the ideas people come up with to improve their side-by-sides. If you’ve done any DIY modifications of your own, jump into the forums and share them. I’d really like to see what you’ve built.

First I got an eyeball estimate on where the filler hole will be.

Then I traced the circle to cut using the hatch. Dont forget to do

the inside circumference, not outer or the whole project will be a disaster.

I then drilled little starter holes all the way around the circle.

Then I used a jigsaw to cut around the circle.

After inserting the hatch with little screws and nuts,

I then sealed the bottom all the way around with black sealant.

I then put it all together. I think it came out rather well.